A minimalistic design out of the darkness.

The Racing Zero family welcomes a new member: the Racing Zero CMPTZN DB! We are excited to introduce this lighter aluminium disc brake variant that benefits the most minimalist look in the Fulcrum range. This strong and responsive wheelset features CULT bearings and the classic 2:1 spoke pattern with oversize double-butted aluminium parts. The 30 mm 2-WAY FIT Tubeless profile aluminium rim, entirely manufactured in Italy, has a unique design, is light and easy to handle. Both hubs feature oversize flanges to optimize the offset of the aerodynamic aluminium spokes. Thanks to all these innovations, the CMPTZ is now a big-impact addition to the Racing Zero DB model!

Technologies:

2-WAY FIT™2-Way Fit™ profile for tubeless and clincher.

Tubeless technology was first used by the auto industry, then by motorcycles and now has reached the cycling industry. After its debut with mountain bikes the moment has come to “put it on the road”, and that’s what we propose to do.

We have developed our 2-Way Fit™ technology to ensure the perfect compatibility of our tubeless rims with normal clincher types and tubes. 2-Way Fit™road bike wheels are perfectly multipurpose for tackling every situation. Thanks to a special impression in the valve area, the tubes are fitted with maximum precision while keeping the tube perfectly stable inside the tyre. Housing the valve for tubeless tyres is also risk-free, with the unquestionable advantage that there are never any air infiltrations caused by non-ideal positioning when fitting.

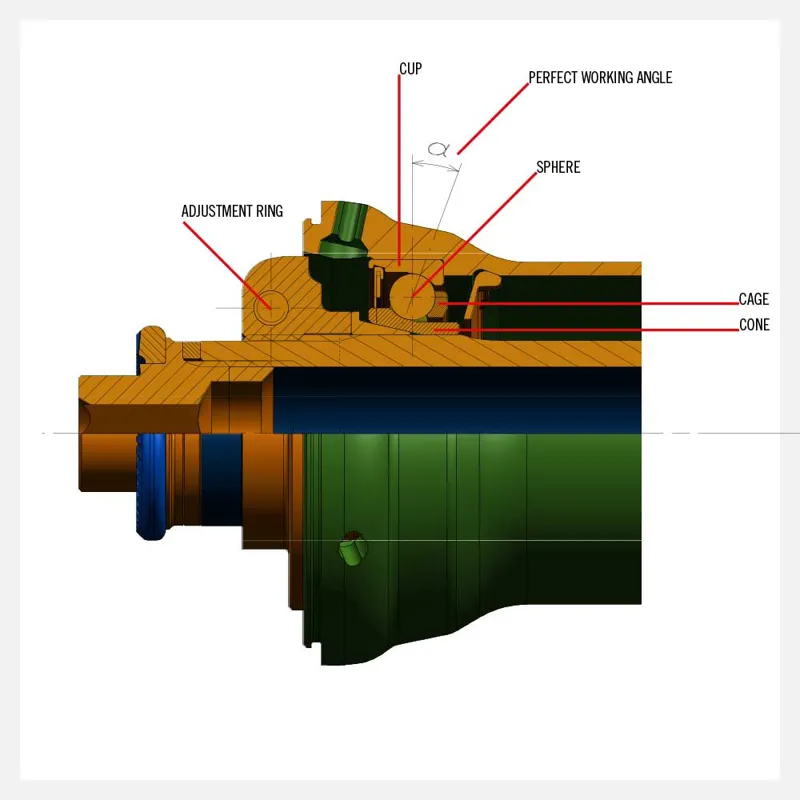

CULT™ - CERAMIC ULTIMATE LEVEL TECHNOLOGY™

CULT™ - CERAMIC ULTIMATE LEVEL TECHNOLOGY™Behind this project is the exclusiveness of Cronitect® steel, using “Advanced by FAG” technology by Schaeffler Group employed for the bearing races. This steel is resistant to corrosion of the highest level until the point that no grease is necessary for lubrication, maybe just a small amount of oil. The top quality ceramic balls, thanks to the absence of lubricating grease and the precision machine of the cup and cone technology, allow to reduce the friction coefficient drastically and then increase the smoothness of triathlon and road bike wheels by as much as 9 times compared to standard bearings. An outstanding result was achieved by using cutting-edge technologies in the field of materials processing.

RDB™ RIM DYNAMIC BALANCE

RDB™ RIM DYNAMIC BALANCEThe concept is simple and elegant: balance the weight of the gasket, with an item of similar weight placed on the exact opposite side.

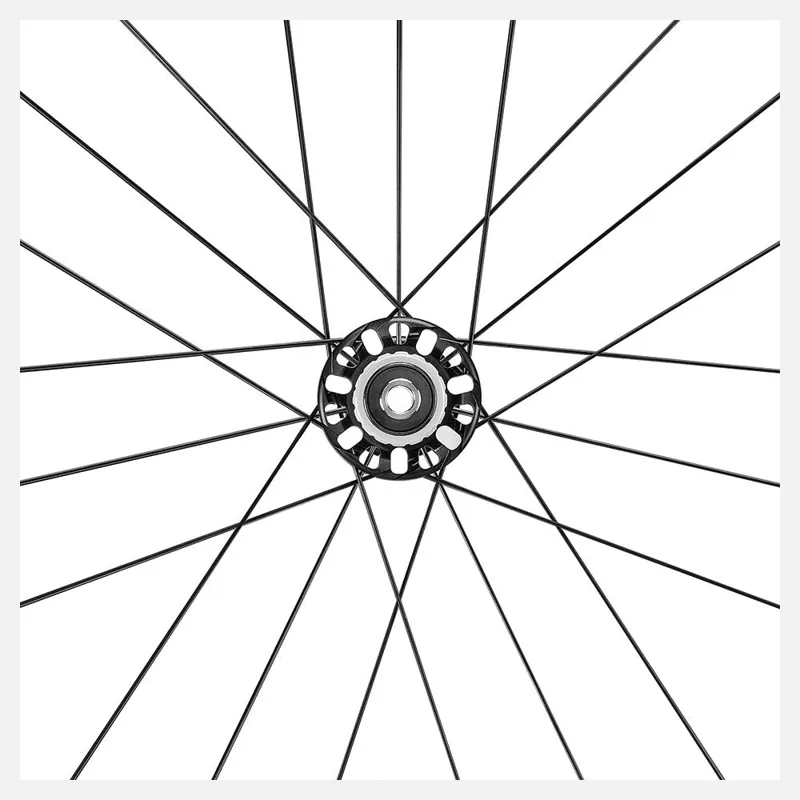

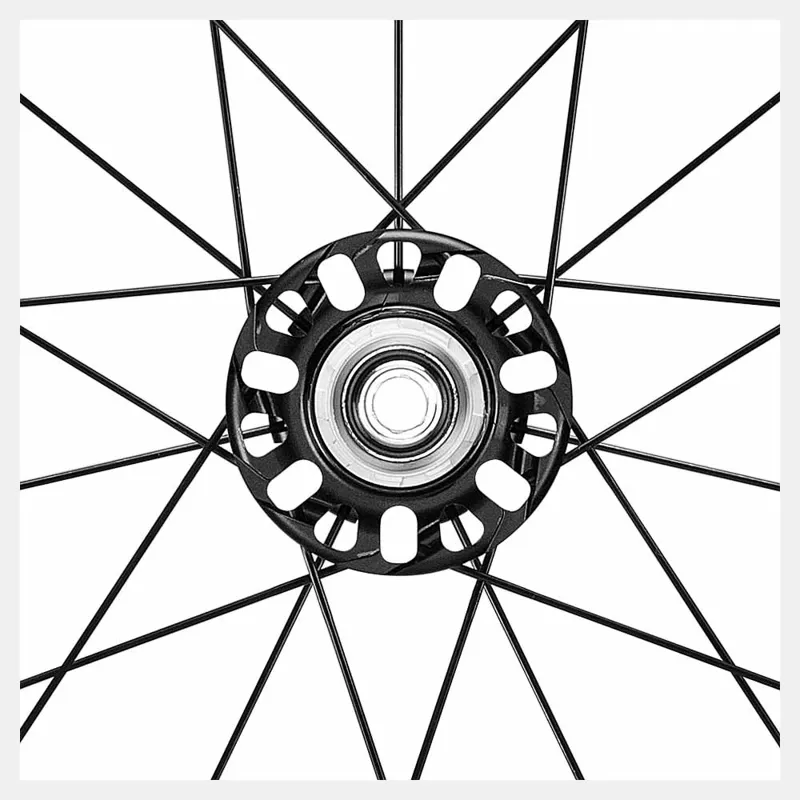

2:1 TWO-TO-ONE™

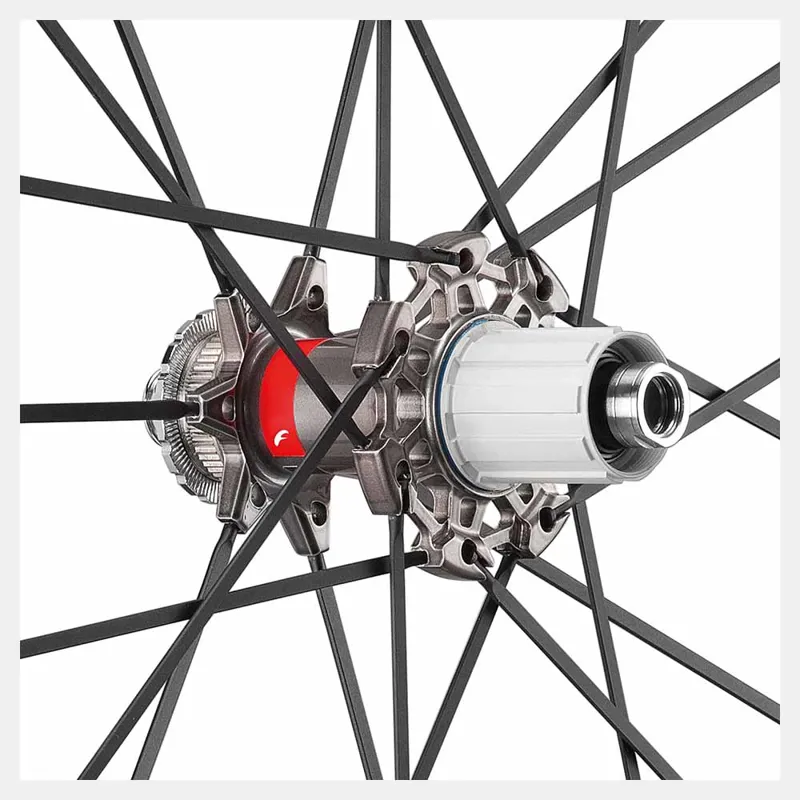

2:1 TWO-TO-ONE™When you push on the pedals, the rotational force on the sprocket induces a slackening of the freewheel spokes with a consequent loss of rim tension. This results in undesirable flex of the whole wheel and an unavoidable loss of energy. Fulcrum® has solved this classic cycling problem with its 2:1 Two-to-One™ Spoke Ratio patent, by doubling the spokes in the critical zones.

2:1 TWO-TO-ONE SPOKE RATIO™ - DISC BRAKE

2:1 TWO-TO-ONE SPOKE RATIO™ - DISC BRAKEA system that is as simple as it is effective, the result of the ingenuity of Fulcrum® engineers and attentive observation of the results of the tests performed on the wheels on a daily basis.

These tests made it possible to understand that the forces that act on the sides of the wheels, and therefore on the spokes, are extremely different; but what’s more, the differences between the front and rear wheels are also evident and significant. The front wheel, in fact, has to remain stable even during braking of the disk on the left side, and the rear wheel, in addition to the sprocket set, has to compensate for the traction of the force on the chain side.

DRSC™ - DIRECTIONATED RIM-SPOKE COUPLING

DRSC™ - DIRECTIONATED RIM-SPOKE COUPLINGExclusive rim/spoke coupling system. It allows the rim, spokes, nipples and hub to align properly with the same tensioning value in all areas.

MOMAG™

MOMAG™What is MoMag™?

A magnet and lots of ingenuity. This was what led to the patent for the well-tested “Mounting Magnet” system, or MoMag™. The nipples, once inserted inside the rim via the valve hole, are “guided” to the point of connection with the spoke by means of the magnet. This simple but ingenious system makes it possible to have wheels without holes on the upper bridge, but with spokes tensioned by traditional nipples!

No holes on the rim mean that the rim is uniform at every point, free from stress points or zones of weakness and, for the clincher profiles no rim tape is required, to the benefit of weight reduction. The advantages are immediately clear: greater rim lifetime, greater resistance to fatigue, the possibility to give the spokes greater tension, and greater stiffness which, in terms of performance, mean greater reactivity and acceleration.

ANTI-ROTATION SYSTEM™

ANTI-ROTATION SYSTEM™This new system raises the concept of spoking to a new level of performance for road bike and triathlon wheels ( and mtb too) The Fulcrum® engineers have redesigned the spokes and the hub housings to create a solid and unmoveable whole. The result is that the spokes

a) will never lose their initial tension, thus keeping the wheel perfectly reactive and centred

b) will remain in the position that has been studied in the wind tunnel tests to ensure the best aerodynamic penetration possible.

F.I.C. FULCRUM IDENTIFICATION CARD - 100% HANDMADE QUALITY

F.I.C. FULCRUM IDENTIFICATION CARD - 100% HANDMADE QUALITYRight from its inception, Fulcrum® has been marked by the feature that continues to this day: is to design, prototype and industrialise all the wheels characterised by the red “F”. Indeed these take shape inside of the R&D, the leading-edge department that represents the beating heart of the Italian company.

Every single component of the wheel, the materials chosen and the technologies applied are the tangible result of the effort that Fulcrum® makes every day to give you maximum performance and reliability.

TRACEABILITY

TRACEABILITYA guarantee of quality

The keyword for our products is traceable.

If you find a little label attached to any Fulcrum® product, do not remove it. It will provide you with a guarantee in case of an ascertained defectiveness of a production batch, and so the component needed or wheel will be traceable. All this because, devoted to its mission, Fulcrum® demands absolute perfection and safety for its customers.

AFS AXLE SYSTEM™

AFS AXLE SYSTEM™The Axial Fixing System™ is the solution developed by Fulcrum® to fix the disc brake to the hub. The constraint granted by the butt area of the release mechanism, greater than in familiar standard ones, makes it possible to obtain greater structural rigidity and therefore more precise and powerful braking.

WIDE RIM TECH

WIDE RIM TECHFulcrum®’s R&D department, following requests from the competition circuit, has worked to create rims that are wider than before, about 4 mm or more than previously. This technical choice provides an ideal basis for 25/28mm tyres, the sizes currently popular. This ensures stability, excellent handling and superior comfort.

UNDRILLED RIM BED

UNDRILLED RIM BEDNo holes on the bridge connector mean that the rim is uniform at every point, free from critical areas subject to stress. The advantages are immediately clear: less weight, longer lasting rims, greater resistance to fatigue, the possibility of giving the spokes more tension and more stiffness which, in terms of performance, means improved responsiveness and acceleration.

CUP & CONE

CUP & CONEThe cup-and-cone bearing differs from the classic cartridge bearing because it works in perfect alignment with the forces involved, weight and thrust from the frame, as the bearings run in a race positioned directly opposing these forces.

HIGH STRENGTH ALUMINUM

HIGH STRENGTH ALUMINUMSpecial aluminium - the best aluminium wheels require carefully chosen materials. For "High strength Aluminum", Fulcrum® R&D uses only the best aluminium alloy 6082, with artificial ageing T6 temper that stabilises the alloy and gives it maximum life and reliability. Aluminium 6082 has the highest strength of the 6000 series and has replaced 6061 in many applications. It is generally used for high-stress applications.

CARBON HUBS

CARBON HUBSIn line with their aim to save every possible gram of weight and to choose the most advanced technological solutions, the R&D department has developed a seamless carbon hub. The fibre selected is woven at 90 degrees, for the enhanced balance of torque when pedalling.

PLASMA FREEHUB

PLASMA FREEHUBThe Plasma treatment makes the aluminium especially hard and resistant to surface abrasion and wear. This has allowed the thickness of materials to be reduced to a minimum, achieving advantages of lighter weight, while maintaining lifespan and reliability.

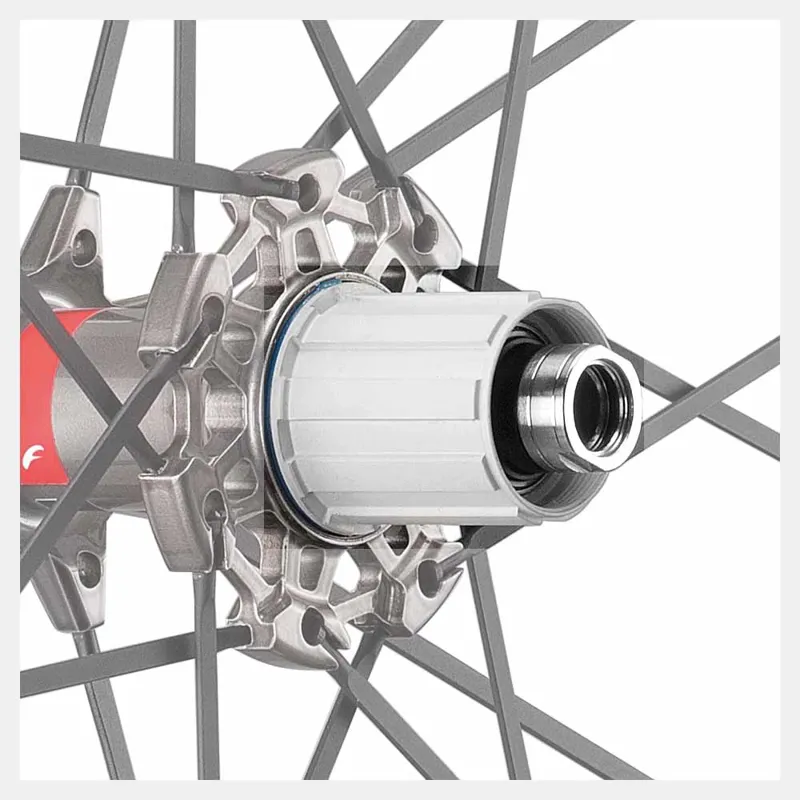

OVERSIZE FLANGE

OVERSIZE FLANGEThe Oversize Flange was developed from the need to create a system to transmit every watt to the ground without dispersion, stiffening the wheel system where necessary, without having to add spokes or superstructures that increase weight. The oversize flange uses physics to solve the problem. It increases dishing and enables spokes to be shortened. Doubling the spokes creates a balanced system that is excellent at transmitting torque.

MONOBLOCK HUB FOR DISC

MONOBLOCK HUB FOR DISCThe rear hub of a top-quality disc brake wheel is a technical problem to be solved. Fulcrum®’s R&D department found itself facing a fundamental choice: on which side to put the oversize flange of the Two-to-one™ system? Disc or sprocket side? Without question - must stay on the sprocket side. To combat the loss of braking power from flex and torque of the connector between the two sides of the hub, a special one-piece system has been devised with internal stiffening ribs.

SPECIFIC NIPPLE HOUSING

SPECIFIC NIPPLE HOUSING7% more reliable.

Such a small part, yet so important. The nipples and their housing are some of the most important elements that are taken into account during the design of a wheel. During the development of the new E-Mtb Fulcrum rims, a lot of work was put into this aspect. The housing has been re-designed and now it makes it possible to eliminate completely the nipples' hard work.

Thanks to special housing, with side guides on both sides, the nipple sets on a stable base, perfectly in position, oriented towards the spoke. This makes it possible to make the distribution of the tensions in the rim more even, creating thus perceptible benefits in terms of effort and rigidity: this prevents misalignments under stress and, as a consequence, deformation to the structure.